Many users wonder how their cases will perform under the most demanding and harsh conditions—falls, impacts, temperature changes during air transport, etc. Daily use is a tough test for any case and instrument.

To ensure their products meet the highest standards of quality, protection, and durability, BAM has thoroughly tested their cases at the BAM TEST CENTER laboratories.

All BAM cases that have been tested have successfully passed the rigorous quality control tests they undergo. In cases where even the slightest issue arose, the cases were modified until they successfully passed the demanding tests outlined below.

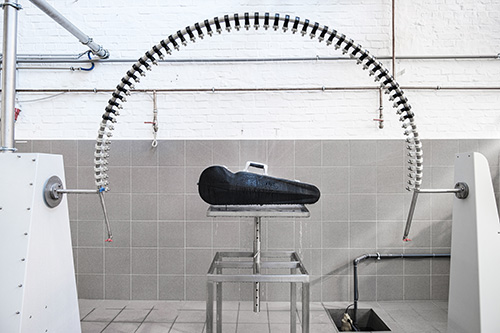

Test 1 | Water Tightness

The case’s ability to remain sealed is tested from different angles to ensure that water does not enter the compartment.

-

Spray arc radius: 1000 mm

-

Arc: 180º

-

Flow rate: 1 l/min

-

Time: 1 hour

Requirements:

No water or moisture should enter the case.

-

Test result: Approved

|

|

Test 2 | Climatic Resistance

The case is exposed to a climatic cycle with 3 different types of weather conditions. After each test with a specific weather condition, the case is left to rest at room temperature for a period of 2 hours. The test is repeated over 3 cycles.

|

Climatic Cycle #1 |

Climatic Cycle #2 |

Climatic Cycle #3 |

|

|

|

Requirements:

-

No degradation in the case shell

-

No defects in the joints, closures, or seams

-

No discoloration or corrosion

Test result: Approved

|

|

Test 3 | Conveyor Belt Rolling Test with Obstacles

The test evaluates the rolling resistance on an uneven surface. Three 15 km-long journeys are carried out on a conveyor belt with obstacles and a 5 kg load inside the case.

-

Load in the case: 5 Kg

-

Conveyor belt with obstacles according to UNE-EN 1888:2012 standard

-

Distance traveled: 3 x 15 Km

-

Break between trips: 1 hour

-

Speed: 4 km/h approx.

-

Inclination: 60º ±5º from the horizontal plane

-

Additional weight: 5 Kg on the handles

Requirements:

After each test trip, the condition of the wheels and handles is evaluated. No breakage of the handles, grips, wheels, or axles should occur. Minor deformations are allowed as long as the functionality of the case is not affected.

Test result: Approved

|

|

Test 4 | Free Fall Test

A series of drops are performed from different angles and faces of the case, with a total of 26 drops from a height of 2.3 meters and a 5 kg load inside the case.

-

Load in the case: 5 Kg

-

Height: 2.3 m

-

Floor material: 2 mm PVC-coated steel plate

-

Temperature: 23º C ±2º C (conditioned room for 25 hours)

-

Number of drops: 26

-

One drop from each face of the case (6 times)

-

One drop from each side of the case (12 times)

-

One drop from each corner of the case (8 times)

-

Requirements:

Visible defects are allowed as long as they do not affect the functionality of the case. The interior of the case must not be accessible from the outside when it is closed.

Test result: Approved

|

|

|

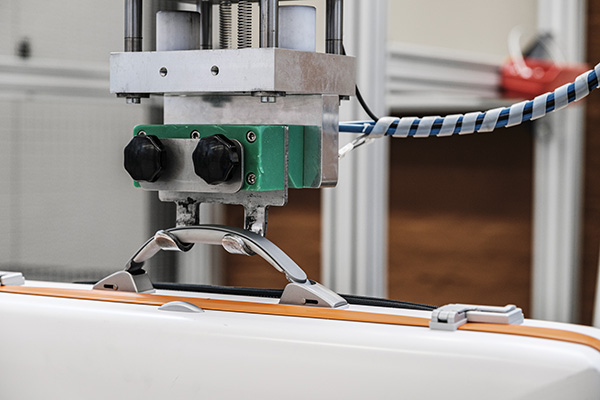

Test 5 | Repeated Lifting Test

The case is repeatedly lifted by its handles or grips and returned to the ground for a total of 8000 cycles.

-

Load in the case: 5 Kg

-

Application of force: Center of the handle or grip

-

Lifting height: 100 mm

-

Duration of each lift: 1 second

-

Lifting speed: 0.1 m/s

Requirements:

8000 cycles without any damage to the case or its handles. Minor deformations are allowed as long as the functionality of the case is not affected.

Test result: Approved

|

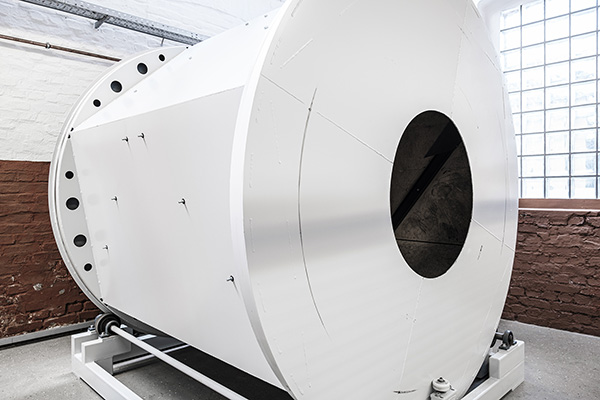

Test 6 | Spinning Test

The case is placed inside a spinning drum with a 5 kg load inside. This tests the case's continued resistance to impacts as well as abrasion on the outer layer.

-

Load in the case: 5 Kg

-

Rotation: 1 rev./min – 4 rev./min

-

Test duration: 1 hour

Requirements:

No breakage should occur in the shell, handles, grips, wheels, or axles of the case. Minor deformations are allowed as long as the functionality is not affected.

Test result: Approved

|

||

|

|

|